|

Ways of Reducing Friction in Machines

Just as friction has

advantages, which are the uses it can be put into,

see uses of

friction, it also has disadvantages. It causes wear of machine parts,

and it uses up energy and therefore reduces the efficiency of machines. Here are

different ways friction can be reduced in machines.

Reducing Friction by Applying Oil

A common way of reducing

friction is to lubricate the surfaces of machines, which slid over each other

with oil. With a layer of oil between the machine surfaces, friction is reduced

as the parts slid over each other.

Oils lubricate better when hot

because they are less viscous as they become hot. This explains why engines

usually don’t start easily in cold weather when the oil is cold, but the

engine becomes more efficient as it warms up.

However, if an engine overheats

and the oil gets too hot, it can get denatured as a result of the chemical

decomposition of its structure that could occur.

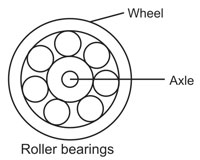

Reducing Friction by Using Ball

or Roller

Bearings

Ball or roller bearings is used

to reduce friction where a wheel is turning on an axle. Ball or roller bearings

are like wheels, which roll round the axle as the wheel turns.

They wear out much slowly, as

they apply static friction, rather than trying to overcome kinetic friction.

See

coefficient of kinetic friction here

See

kinetic friction here

See static friction here

See

coefficient of static friction here

See

friction here

See

calculating friction here

|